Applications

Aluminum Profile Processing – The Optimal Solution for Modern Industrial Applications

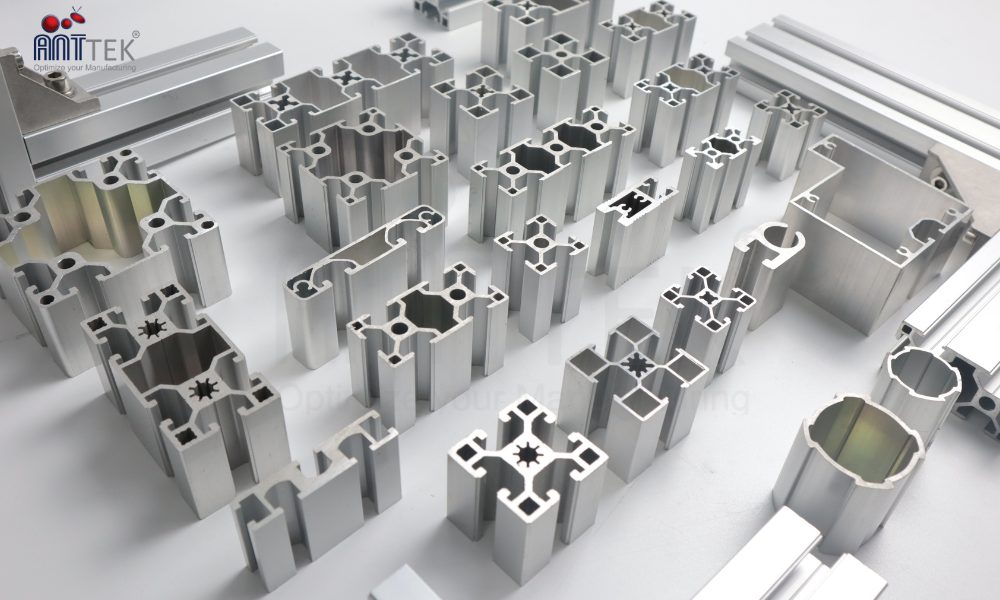

Aluminum profiles are increasingly asserting their importance in various industries such as construction, mechanical engineering, interior design, and component manufacturing. Precision aluminum profile processing not only delivers high-quality products but also meets the diverse demands of the market.

1. What is an Aluminum Profile?

An aluminum profile is a product made from pure aluminum through extrusion processes to form specific shapes as required. With properties such as lightweight, high durability, corrosion resistance, and recyclability, aluminum profiles have become a preferred choice across multiple sectors.

Common Applications of Aluminum Profiles:

- Aluminum doors, partitions, and railings.

- Machine components and automation equipment.

- Interior products such as tables, chairs, and shelving.

2. Aluminum Profile Processing Workflow

2.1. Mold Design

The first step in aluminum profile processing is creating design drawings to ensure precise shapes and dimensions. Advanced CAD/CAM technology optimizes accuracy and production efficiency.

2.2. Aluminum Extrusion

Molten aluminum is pushed through a die to form the desired profile shape. This is a critical stage that determines the product’s strength and durability.

2.3. Surface Treatment

To enhance aesthetics and durability, aluminum profiles undergo various surface treatments, such as:

- Anodizing: Increases oxidation resistance.

- Powder Coating: Ensures vibrant colors and long-lasting durability.

- Polishing: Provides either a glossy or matte finish, depending on requirements.

2.4. Precision Machining & Assembly

Final processing steps such as cutting, drilling, and assembling are meticulously performed to create finished products that are ready for use.

3. Outstanding Advantages of Aluminum Profile Processing

- High Durability: Strong load-bearing capacity and excellent corrosion resistance, even in harsh environments.

- Lightweight: Easy to transport and install without compromising structural integrity.

- Aesthetic Appeal: Available in various designs and colors, suitable for diverse applications.

- Cost-Effective: Reasonable pricing with a long product lifespan, providing great value for investment.

4. Development Trends in Aluminum Profile Processing in Vietnam

In Vietnam, the demand for aluminum profiles is increasing rapidly, driven by the growth of the construction and industrial sectors. Local manufacturers are investing in advanced processing technologies to enhance product quality and meet international standards.

5. Anttek Vietnam – Leading Aluminum Profile Processing & Assembly Provider

Anttek Vietnam is a pioneering company specializing in aluminum profile processing and industrial aluminum frame assembly. With a team of experienced experts, Anttek is committed to delivering optimal solutions for businesses, helping them reduce costs and improve operational efficiency.

For more information, please contact:

Factory: Lot 6, Lai Xa Industrial Zone, Kim Chung Commune, Hoai Duc District, Hanoi City, Vietnam.

Hotline: +84 988.688.336

Email: truong.nx@anttekvietnam.com

Website: https://anttekvietnam.vn