Applications

Anttek . aluminum profile production process

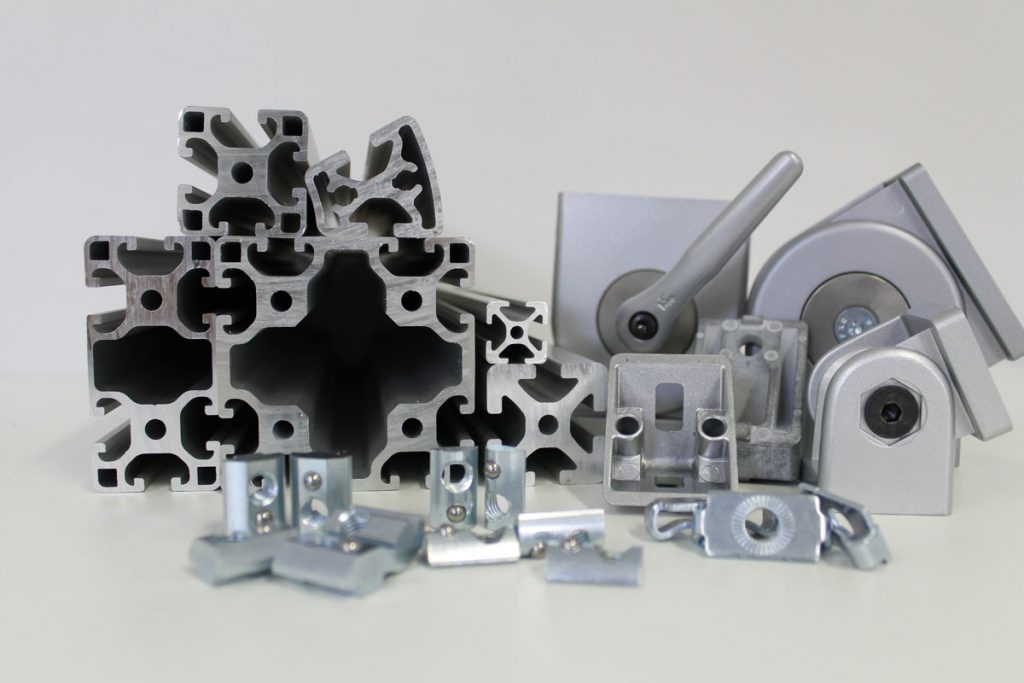

Customers already know a lot about the advantages and popular applications of Aluminium Profiles in life as well as in many different industries. However, not everyone knows how to create aluminum profiles. To better understand the process of creating aluminum profiles with many different forms, please follow the information that our Anttek company shares below.

Aluminum profile production process:

Import material

The material we refer to here is aluminum ingot, also known as raw aluminum ingot.

Analysis of ingredients

Currently imported aluminum billets are mainly aluminum alloys, which means that aluminum contains various impurities rather than pure aluminum. For standard aluminum billets, they will be put into a furnace at high temperature to melt the material.

Further casting materials

After the aluminum is smelted and converted to liquid form, the furnace temperature will be increased so that the aluminum reaches the boiling point, in this process the components other than aluminum will determine which aluminum the finished product will be. After the liquid aluminum has boiled, it will be poured into the mold to form Billet aluminum billet, also known as Billet billet.

Die-casting aluminum profiles

After the fuel treatment and Billet forming process in step 3, the aluminum will be cut into standard segments. These standard billets will be heated to soften the billet and then pressed into designed molds to form square aluminum, round aluminum or sheet aluminum.

- Hardness treatment

After the process of pressing aluminum molds into different shapes, the aluminum bars will be cooled by solvent water and then put into an autoclave to create the necessary hardness for the aluminum profiles.Test finished products and surface treatment

After hardness treatment engineers will begin to check which aluminum bars qualify by different physical properties such as ductility, hardness and tensile strength of aluminum.

For satisfactory aluminum profiles, the surface will be treated such as electrostatic painting, color painting, wood grain paint….

Hopefully the information that our Anttek company has shared will help customers better understand the current production process of aluminum profiles.